Tennis Court Resurfacing: Complete Guide by Elitecourt

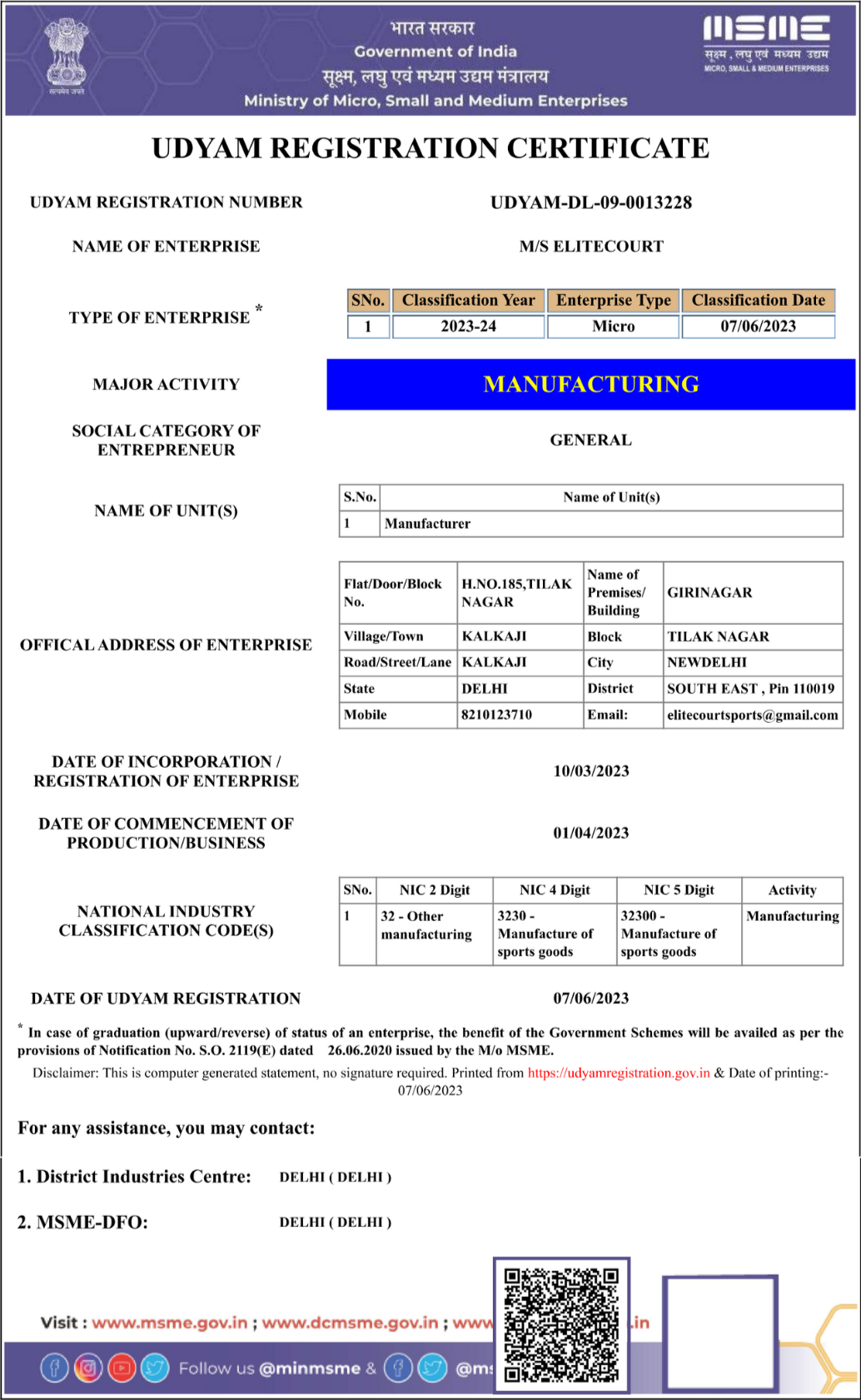

With years of expertise in synthetic acrylic sports flooring, Elitecourt stands as one of India’s most trusted manufacturers for tennis court resurfacing materials. Known for reliability, innovation, and precision, Elitecourt delivers surfaces that meet international performance and safety standards.

Table of Contents

When your tennis court starts showing cracks, fading color, or uneven bounce, it’s a clear sign that tennis court resurfacing is due. This process not only restores the court’s playability but also enhances safety, performance, and durability. In this detailed guide, we’ll explore everything about resurfacing—what it involves, why it’s essential, and how Elitecourt’s acrylic sports flooring materials set the industry benchmark.

Introduction: Why Tennis Court Resurfacing Matters

Every tennis court, no matter how well-built, endures natural wear over time. Continuous foot traffic, UV exposure, and weather elements gradually erode the surface. The once smooth, vibrant playing area may start to fade, crack, or lose traction — compromising both aesthetics and playability.

That’s where tennis court resurfacing comes in; moreover, this process goes far beyond cosmetics—it serves as a vital step in preserving a professional-grade court’s performance and safety. Resurfacing involves cleaning, repairing, and recoating the surface with high-quality acrylic materials, ensuring it looks brand new and performs like one too.

When left unattended, surface damage gradually worsens; consequently, players may experience uneven bounce, reduced traction, and even increased injury risks. Regular resurfacing using premium materials, like those manufactured by Elitecourt, can restore your court’s original performance and extend its lifespan significantly.

In short, resurfacing transforms an old, worn-out tennis court into a safe, durable, and high-performing surface — essential for both professional players and recreational users alike.

What is Tennis Court Resurfacing?

Tennis court resurfacing is a restorative process that rejuvenates the top layer of a court without altering its base structure. It involves removing dirt and debris, repairing cracks, leveling the surface, and applying fresh acrylic coatings to create a smooth, uniform finish.

Unlike full reconstruction—which involves breaking down and rebuilding the foundation—resurfacing instead focuses on renewing the existing playable layer through advanced acrylic coating systems; as a result, it’s faster and far less disruptive.

A typical resurfacing job includes:

- Cleaning and surface preparation to remove dust, algae, or contaminants.

- Filling cracks and low spots using acrylic-based patching compounds.

- Applying multiple layers of acrylic resurfacer, pigmented coatings, and texturized finishes.

- Re-striping the court lines with precision for visibility and regulation compliance.

Resurfacing ensures the court maintains consistent bounce, friction, and traction, aligning with international standards. Elitecourt engineers its acrylic materials to deliver high performance, superior weather resistance, and vibrant color retention, which makes them ideal for both indoor and outdoor tennis facilities.

When Should You Resurface Your Tennis Court?

Every tennis court has a lifecycle, and knowing when to resurface can prevent larger issues down the line. Signs that indicate resurfacing is needed include:

Visible Cracks and Surface Damage

Cracks are the first and most obvious sign. They not only affect appearance but also compromise playability and safety. Even small cracks can expand due to temperature changes or moisture, making timely resurfacing crucial.

Fading Color and Dull Finish

Acrylic coatings are exposed to UV rays daily, which gradually fade their color intensity. When the once vibrant surface starts to look pale or patchy, resurfacing with new acrylic layers brings back the court’s brilliance.

Uneven Bounce and Poor Ball Response

As the surface deteriorates, it directly affects how the ball interacts with the court; therefore, resurfacing becomes essential to restore accurate bounce and player confidence. Players may notice inconsistent bounce, reduced speed, or poor traction—all signs that resurfacing is overdue.

Water Pooling or Drainage Issues

Puddles or standing water after rain are indicators of surface unevenness. These areas can worsen over time, leading to cracks and peeling.

Recommended Resurfacing Frequency

Most tennis courts benefit from resurfacing every few years, depending on usage, location, and maintenance practices. Courts in high-traffic clubs or extreme climates may require more frequent attention.

By identifying these early signs, facility owners can plan resurfacing in time; thus, they prevent small surface issues from escalating into major structural problems. Using Elitecourt’s acrylic flooring systems ensures the repaired surface not only looks new but performs exceptionally well under all playing conditions.

Benefits of Tennis Court Resurfacing

Resurfacing isn’t just routine maintenance; instead, it represents a long-term investment in safety, player performance, and visual appeal. Let’s explore why it’s essential:

Enhanced Player Safety

A smooth, consistent surface reduces the risk of slips, trips, and falls. Fresh acrylic coatings provide the ideal balance between grip and glide, ensuring safe movement and quick footwork.

Improved Playability

Resurfacing restores uniform ball bounce and traction, which are critical for professional-level play. Elitecourt’s textured acrylic coatings offer optimal surface speed and control, enhancing every game.

Aesthetic Appeal

A vibrant, well-marked tennis court creates a professional atmosphere and boosts the facility’s visual appeal. Elitecourt’s UV-resistant pigments maintain color brilliance even after years of exposure.

Long-Term Surface Protection

Resurfacing acts as a protective barrier against environmental wear, UV damage, and moisture intrusion—extending the lifespan of the court and minimizing costly repairs later.

Increased Property Value

A newly resurfaced tennis court adds value to residential complexes, sports clubs, and institutions, making it a worthy long-term investment.

In essence, resurfacing transforms an aging tennis court into a high-performance arena that meets the demands of modern play.

Elitecourt’s Expertise in Tennis Court Resurfacing Materials

As a leading manufacturer of synthetic acrylic sports flooring in India, Elitecourt has established itself as a trusted partner for high-performance court materials. The company’s products are engineered to meet global standards of quality, durability, and safety.

Advanced Acrylic Systems

Elitecourt formulates its acrylic resurfacing systems to provide optimal traction, vibrant colors, and lasting weather resilience. They are suitable for various court types, including tennis, basketball, and multi-sport surfaces.

Key Features of Elitecourt’s Resurfacing Materials:

- Excellent UV resistance to prevent fading.

- Anti-slip surface texture for enhanced player safety.

- Superior adhesion to asphalt and concrete bases.

- Environmentally friendly composition with low VOC emissions.

- Customizable colors to match institutional or brand themes.

Trusted by Professionals

Sports facilities, clubs, and educational institutions across India choose Elitecourt’s materials, which deliver consistent performance and lasting aesthetics.

In addition, Elitecourt’s in-house R&D and strict quality assurance processes ensure that every batch not only meets but consistently exceeds industry benchmarks. For sports flooring solutions that combine beauty with function, Elitecourt remains the name professionals trust.

Transform Your Sports Facility Today!

Contact us for high-quality synthetic sports flooring material and elevate your space!

Step-by-Step Process of Tennis Court Resurfacing

Resurfacing a tennis court is a detailed, methodical process that requires precision, the right materials, and a deep understanding of surface behavior. While Elitecourt focuses on manufacturing the highest quality synthetic acrylic resurfacing systems, understanding the overall process helps clients and contractors achieve the best possible results using those materials.

Step 1: Cleaning and Surface Preparation

The resurfacing process begins with thorough cleaning. Contractors remove every speck of dust, debris, and algae, often using pressure washing to keep the court surface spotless and free of contaminants that could affect adhesion.

Once the surface dries thoroughly, contractors then proceed to inspect the entire court for damage; this step, in turn, determines the level of preparation needed for flawless resurfacing. Any loose particles or peeling coatings are scraped and cleaned off. Proper surface preparation ensures that the new acrylic layers bond perfectly, preventing issues like peeling or bubbling in the future.

Step 2: Crack Repair and Patching

Next, all visible cracks and surface irregularities are addressed. Using acrylic patching compounds, technicians fill cracks, holes, and depressions to create an even surface. These materials are flexible enough to expand and contract with temperature changes, minimizing future cracking.

Technicians level uneven spots with patch binders to ensure consistent bounce and traction. Elitecourt engineers its materials to adhere seamlessly to repaired areas, creating a flawless finish once resurfacing begins.

Step 3: Application of Acrylic Resurfacer

After repairs, a base layer called the acrylic resurfacer is applied. This layer acts as a foundation for the color coatings that follow. It fills in minor surface texture differences and provides a uniform base.

Elitecourt designs its resurfacing systems for maximum adhesion and smoothness. Depending on the court’s condition, contractors typically apply one or two coats of resurfacer using rubber squeegees.

Step 4: Color Coating and Texturing

Once the resurfacer dries, multiple coats of colored acrylic coatings are applied. These layers give the court its distinctive color and play characteristics. The coatings are formulated with fine silica sand to control texture, ensuring the right amount of grip and ball response.

Elitecourt offers a wide range of UV-stable pigments, from classic green and red to contemporary blue and purple hues, all resistant to fading even under intense sunlight.

Step 5: Line Marking and Final Touches

Finally, precise white line markings are added according to ITF (International Tennis Federation) standards. Proper line placement ensures fair play and professional aesthetics.

After completing precise line painting, technicians allow the court to cure completely before use; consequently, each coating layer stabilizes and performs exactly as intended. The result? A beautifully resurfaced tennis court with elite performance, durability, and appearance.

Expert Tip: Avoid using the court for at least 3–5 days after resurfacing to allow proper curing and coating stabilization.

Choosing the Right Acrylic Resurfacing System

Selecting the ideal resurfacing system is key to achieving long-term performance. With Elitecourt’s premium-grade acrylic formulations, clients can customize their courts for the desired look and feel.

Understanding the Layers

A complete resurfacing system typically includes:

- Acrylic Resurfacer – Provides a smooth, adhesive base.

- Color Coats – Offer vibrant color and surface traction.

- Top Coating – Adds durability and UV protection.

- Line Markings – For regulation play and clear visibility.

Each layer plays a unique role in performance. Elitecourt designs its systems to work in harmony so they maintain optimal consistency and endurance even under heavy usage.

Surface Texture & Speed Options

Different players and clubs prefer varied court speeds—some like faster courts, others prefer slower surfaces for control.

Elitecourt’s coatings can be adjusted for:

- Medium Pace – Ideal for most professional and recreational courts.

- Slow Pace – Adds more grip and longer rallies.

- Fast Pace – Provides a smoother, less textured surface for quicker play.

The flexibility to customize makes Elitecourt’s acrylic systems suitable for international standard tournaments and local clubs alike.

Acrylic Resurfacing vs. Other Court Surfaces

While multiple materials are used for tennis courts worldwide, acrylic resurfacing stands out as the most versatile and cost-effective for long-term performance. Let’s compare it with other popular surface types:

| Surface Type | Maintenance | Performance | Durability | Weather Resistance |

|---|---|---|---|---|

| Acrylic (Elitecourt) | Low | Consistent bounce, customizable speed | High | Excellent |

| Clay | High | Slower play, high grip | Moderate | Poor in rain |

| Grass | Very High | Fast play, traditional | Low | Poor |

| Asphalt/Concrete (Uncoated) | Moderate | Hard surface, high impact | High | Fair |

Why Acrylic Wins

- Provides consistent playability across climates.

- Easier to maintain and clean.

- Offers vibrant color options and professional aesthetics.

- Reduces impact stress on players’ joints.

With Elitecourt’s advanced formulations, acrylic surfaces not only deliver superior grip and resilience but also maintain vibrant color for years; hence, they remain the top choice for modern sports facilities.

Transform Your Sports Facility Today!

Contact us for high-quality synthetic sports flooring material and elevate your space!

Maintaining a Resurfaced Tennis Court

Proper maintenance is essential; therefore, consistent care ensures your resurfaced court remains in pristine condition for many years. Even though Elitecourt’s acrylic systems are designed for durability, routine care is vital.

Routine Cleaning

- Sweep or blow away leaves, dust, and debris regularly.

- Wash the surface occasionally using mild detergent and soft brushes.

- Avoid harsh chemicals that might degrade acrylic coatings.

Drainage Maintenance

Keep surrounding areas free from debris that may block drains. Standing water can accelerate surface deterioration, especially at the base of the coatings.

Preventive Maintenance

- Inspect cracks or peeling annually.

- Restrict heavy vehicle movement or sharp objects on the court.

- Cover the court during long periods of non-use.

Pro Tip: Always use soft-soled shoes to prevent abrasion.

By combining routine maintenance with Elitecourt’s premium coatings, facility owners can maintain a pristine and professional-looking court for many years.

Environmental and Quality Standards in Resurfacing Materials

Sustainability and safety are core priorities for modern sports flooring, and Elitecourt leads in both.

Eco-Friendly Formulations

Elitecourt’s acrylic resurfacing materials are developed using low-VOC (Volatile Organic Compounds) technology. This means minimal emissions during application, contributing to a healthier environment and safer working conditions.

Compliance and Quality Assurance

Elitecourt’s products align with international sports flooring standards, including ITF classifications. The materials are tested for color retention, traction, and surface uniformity to ensure performance consistency.

Furthermore, they comply with environmental guidelines for sustainable manufacturing, thereby ensuring that performance excellence aligns with ecological responsibility.

Durability Meets Responsibility

Elitecourt’s focus on sustainability doesn’t compromise quality. The coatings are engineered to withstand extreme climates, from humid coastal regions to dry, hot terrains—ensuring durability while minimizing maintenance needs.

For more insights into tennis surface standards, refer to the International Tennis Federation’s Court Surface Guidelines

Elitecourt’s Quality Assurance Process

Every tennis court deserves the best-performing surface, and Elitecourt’s quality assurance process guarantees exactly that. From formulation to packaging, each stage of production follows a meticulous quality control system designed to ensure consistency, safety, and excellence.

Rigorous Material Testing

All raw materials undergo strict quality testing before they even enter the manufacturing process. Acrylic polymers, pigments, and additives are checked for purity, adhesion quality, UV resistance, and environmental compliance. This step ensures that every batch meets Elitecourt’s exacting standards.

Once production begins, samples are taken from each batch and subjected to:

- Adhesion strength tests – Ensuring coatings bond firmly to the surface.

- Color consistency analysis – Guaranteeing vibrant, fade-resistant shades.

- Curing and flexibility checks – To verify crack resistance and longevity.

Controlled Manufacturing Environment

Elitecourt’s production facilities use advanced mixing and dispersion technologies to achieve uniform consistency across every container. Temperature, humidity, and particle size are carefully controlled to ensure coating stability and reliable performance once applied.

Field Performance Validation

To ensure real-world excellence, Elitecourt’s resurfacing systems are tested on multiple surfaces and climates across India. These field tests replicate conditions like heat, rain, and wear to evaluate performance over time. Only after passing all these benchmarks do materials earn the Elitecourt seal of approval.

Commitment to Continuous Improvement

Elitecourt’s R&D team, moreover, continuously refines its formulas by integrating client feedback, evolving technologies, and international standards to stay ahead of market expectations. This commitment to innovation and precision makes their tennis court resurfacing systems among the most trusted in the market.

Elitecourt Promise: Every product that leaves the factory is engineered for consistent performance, vibrant aesthetics, and unmatched durability.

Transform Your Sports Facility Today!

Contact us for high-quality synthetic sports flooring material and elevate your space!

Common Mistakes in Tennis Court Resurfacing Projects

Even with premium materials, improper resurfacing practices can lead to premature wear and disappointing results. Knowing these pitfalls can help ensure the best outcomes for your tennis court resurfacing project.

Inadequate Surface Preparation

Skipping or rushing through cleaning and crack repair often leads to poor adhesion. Dirt, oil, or old coating residues can prevent the new layers from bonding properly, causing bubbling or peeling soon after application.

Using Incorrect Material Ratios

Mixing resurfacing materials incorrectly—too much or too little water, for instance—can alter drying times and texture. Elitecourt’s products come with precise usage guidelines to ensure uniform consistency and optimal performance.

Ignoring Climate Conditions

However, applying coatings during extreme heat, cold, or high humidity can adversely impact curing and the final finish; therefore, selecting the right weather conditions is crucial. The ideal resurfacing conditions are moderate temperature and low humidity, ensuring even drying and strong adhesion.

Neglecting Proper Curing Time

One of the most common mistakes is rushing to reopen the court. If the coatings haven’t cured fully, foot traffic can damage the surface, leading to marks or premature wear.

Skipping Maintenance After Resurfacing

Resurfacing is not a one-time solution—it’s part of a long-term care cycle. Ignoring routine cleaning, drainage checks, or periodic inspections can shorten the lifespan of the court surface.

Elite Advice: Follow the manufacturer’s specifications closely. Elitecourt’s products are engineered for precision, and adhering to application guidelines ensures flawless, long-lasting results.

Expert Tips for a Long-Lasting Tennis Court Surface

Whether your court is brand new or freshly resurfaced, following a few professional maintenance habits will help maintain performance and appearance for years.

Regular Cleaning Schedule

Set a monthly routine for removing leaves, sand, and dirt. Organic debris can trap moisture, leading to mold and surface stains. Use soft brooms or blowers, and wash with a mild cleaning solution occasionally.

Manage Drainage Around the Court

Ensure the surrounding areas are properly graded and free of blockages. Water should never pool on the surface after rain. Consistent drainage prevents moisture from seeping into layers and causing blistering.

Protect the Surface from Heavy Loads

Avoid using the tennis court as a parking or storage area. Even temporary placement of heavy objects can dent or damage the coating layers.

Repaint Line Markings Periodically

Over time, UV rays can fade line markings. Repainting them with approved acrylic marking paint maintains both aesthetics and regulation compliance.

Monitor Cracks and Surface Wear

If small cracks or chips appear, address them immediately before they expand. Using Elitecourt’s patching compounds ensures seamless repairs that blend perfectly with the existing coating.

Schedule Periodic Professional Inspection

Additionally, scheduling an annual inspection by a qualified technician helps detect hidden issues such as subsurface cracks or drainage inefficiencies early on—thus preventing costly future repairs.

Pro Tip: Think of tennis court maintenance as routine health care — regular check-ups keep the surface performing at its best for longer.

FAQs

Resurfacing focuses on renewing the top layers of the court to restore performance, while rebuilding involves reconstructing the base or foundation. Resurfacing is faster, less invasive, and ideal when the base structure remains intact.

Most courts benefit from resurfacing every few years, depending on factors like usage, weather exposure, and maintenance. High-traffic or outdoor courts exposed to harsh climates may need more frequent attention.

Surface-level cracks can be repaired during resurfacing using acrylic patching compounds. However, deep structural issues may require additional base work before resurfacing can begin.

A standard resurfacing project typically spans several days, considering cleaning, repairs, multiple coating layers, and drying time. The process should not be rushed to ensure each layer cures properly.

Elitecourt’s materials are precision-engineered acrylic systems known for superior UV resistance, anti-slip texture, and long-lasting color stability. They’re eco-friendly, customizable, and trusted by professional facilities across India.

Conclusion: Why Elitecourt is the Trusted Choice

Tennis court resurfacing is more than just a restoration process—it’s an art of precision, performance, and protection. Choosing the right resurfacing materials ensures that your court not only looks renewed but also performs to professional standards for years to come.

With Elitecourt’s synthetic acrylic sports flooring systems, clients receive world-class formulations that balance durability, traction, and aesthetic excellence. Each batch is tested for quality, ensuring consistent results that meet international standards.

From superior UV resistance to environmentally responsible formulations, Elitecourt’s products exemplify craftsmanship and innovation; moreover, they reflect the company’s long-standing dedication to performance and trust. When you choose Elitecourt, you’re not just resurfacing a court—you’re investing in longevity, performance, and excellence.

Elitecourt: Where innovation meets endurance in every layer of your court.