Tennis Court Flooring Suppliers In India

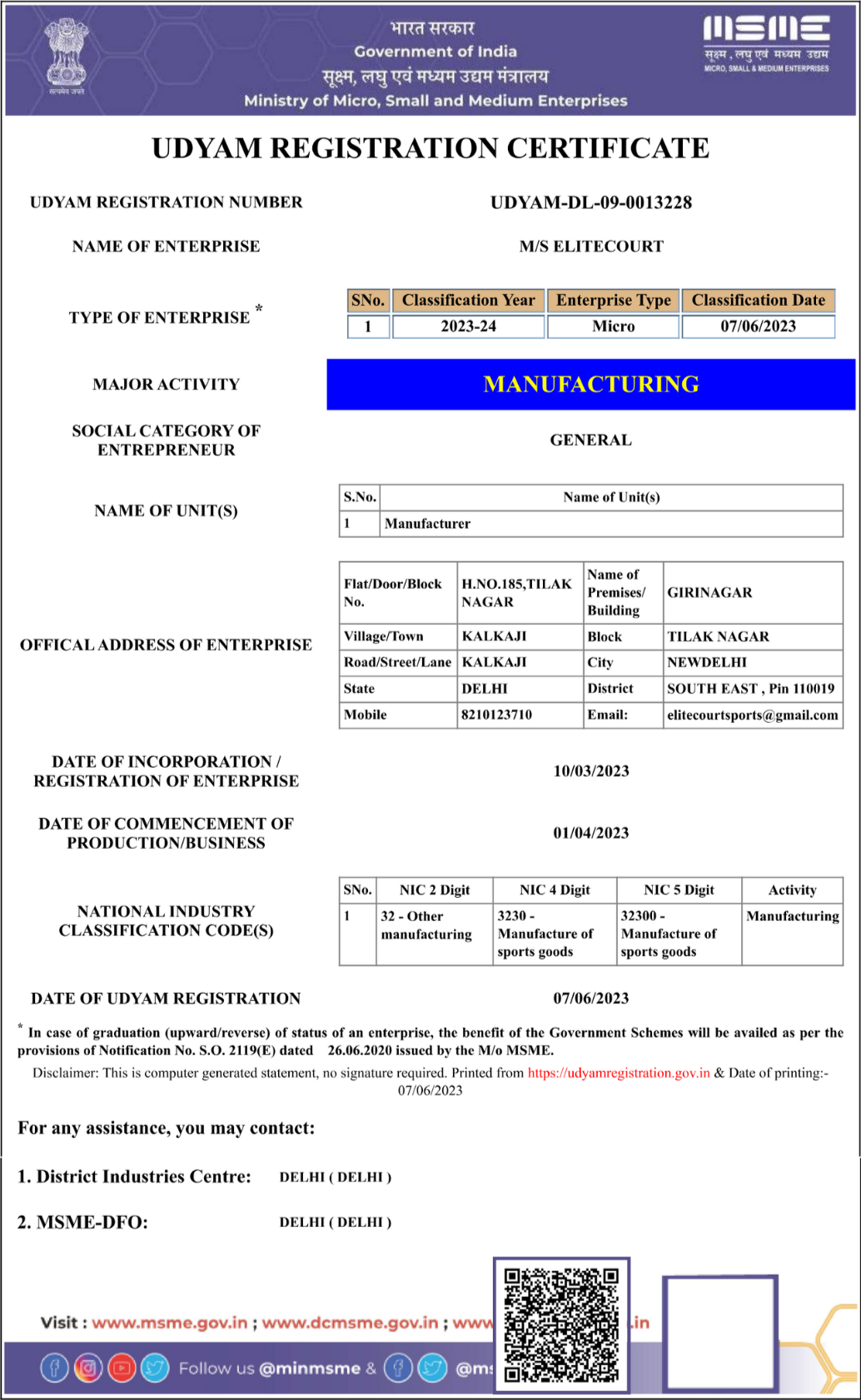

As a leading manufacturer with years of expertise in the sports surfacing industry, Elitecourt is recognized as one of India's most trusted tennis court flooring suppliers. We are dedicated to engineering high-performance synthetic acrylic flooring materials that set the standard for quality, durability, and player satisfaction across the nation.

Table of Contents

Finding the right tennis court flooring suppliers is a critical decision for any sports facility, club, or educational institution. The quality of the playing surface directly impacts player performance, safety, and the overall longevity of the court. A superior court begins with superior materials, and that is precisely where the focus should be. Choosing a supplier is not just about a transaction; it’s about forming a partnership with a manufacturer that understands the science behind a great tennis court. The right supplier offers materials that deliver optimal ball bounce, consistent speed of play, and excellent grip, ensuring champions play every match on a superior surface.

This comprehensive guide will explore the essential aspects of selecting the best materials for your tennis court. We will delve into the different types of flooring available, the key characteristics to look for in a high-quality surface, and the critical role that a specialized manufacturer plays in the process. We aim to equip you with the knowledge needed to make an informed decision, ensuring your investment results in a world-class tennis facility. Whether you are building a new court or resurfacing an existing one, understanding the nuances of flooring materials is the first step toward success.

Understanding the Role of Premier Tennis Court Flooring Suppliers

What truly defines premier tennis court flooring suppliers? It’s a combination of product excellence, innovation, and a deep understanding of the sport’s demands. Unlike general suppliers who may offer a wide range of building materials, specialized manufacturers focus solely on creating sports surfaces. This specialization allows for a level of quality and precision that is simply unmatched.

A dedicated manufacturer like Elitecourt invests heavily in research and development. Our process involves formulating advanced synthetic acrylic systems that deliver specific performance characteristics. We meticulously test our products for UV resistance, abrasion resistance, and flexibility to ensure they can withstand India’s diverse climatic conditions, from intense summer heat to heavy monsoon rains. This commitment to quality means that every batch of material leaving our facility meets stringent international standards.

Working with a specialist manufacturer offers several distinct advantages:

- Consistent Quality: Materials are produced in a controlled environment, ensuring uniformity across every square meter of your court. This consistency is crucial for predictable ball behavior and a fair playing experience.

- Advanced Technology: Specialist suppliers are at the forefront of flooring technology, incorporating the latest polymers and resins to enhance durability, player comfort, and aesthetic appeal.

- Technical Expertise: A manufacturer possesses in-depth knowledge of their products. They provide detailed technical specifications, application guidelines, and support to the applicators who install the court, ensuring the surface achieves perfect results.

- Customization: Leading suppliers can offer a range of systems tailored to different levels of play—from gentle, cushioned surfaces for recreational clubs to fast, competitive surfaces for professional tournaments.

Ultimately, the best tennis court flooring suppliers are more than just vendors; they are partners in your project’s success. They provide the foundational element—the flooring material itself—that determines the court’s performance for years to come.

Why Material Quality is Non-Negotiable

When building a tennis court, the temptation to cut corners on materials can be strong. However, this is a decision that often leads to long-term problems, including premature surface degradation, inconsistent play, and increased maintenance needs. The quality of the synthetic acrylic flooring is the single most important factor in the court’s life cycle.

High-quality materials, sourced from reputable tennis court flooring suppliers, ensure:

- Exceptional Durability: The surface will resist cracking, peeling, and fading, even under constant use and exposure to the elements.

- Optimal Player Safety: A well-formulated surface provides the right balance of grip and slide, reducing the risk of slips and injuries. Cushioned systems can further minimize stress on players’ joints.

- Consistent Ball Response: The surface texture and composition guarantee a true and predictable ball bounce, which is essential for high-quality play.

- Vibrant, Long-Lasting Color: Premium pigments integrated into the acrylic layers maintain their vibrancy, keeping the court looking professional and new for longer.

Investing in quality materials from the start is the most cost-effective decision in the long run. It reduces the frequency of costly resurfacing and ensures the court remains a valuable asset for your facility.

A Deep Dive into Synthetic Acrylic Tennis Court Flooring

Synthetic acrylic flooring is the preferred choice for tennis courts worldwide, from local clubs to Grand Slam venues. Its popularity stems from its incredible versatility, durability, and consistent play characteristics. As experienced tennis court flooring suppliers, we specialize in these multi-layered systems, engineering each layer to perform a specific function.

A standard synthetic acrylic court surface is a system built layer by layer on a stable base, typically asphalt or concrete. Each layer bonds chemically to the one below it, creating a monolithic, resilient, and weatherproof surface.

Let’s break down the typical layers of a high-performance acrylic tennis court system:

The Base: Asphalt or Concrete

The foundation of any great tennis court is a properly constructed base. While we, as suppliers, provide the surface materials, we emphasize the importance of a well-drained, stable, and precisely leveled asphalt or concrete slab. Imperfections in the base will eventually appear in the final surface.

The Primer/Adhesion Promoter

This is the first liquid layer applied. Its primary role is to ensure a powerful bond between the structural base (asphalt/concrete) and the subsequent acrylic layers. A high-quality primer prevents delamination and is crucial for the longevity of the entire system.

The Resurfacer/Filler Coats

Applied over the primer, these acrylic layers are filled with fine aggregates. Their purpose is to fill minor voids in the base, smooth the surface, and establish the foundational texture for the court. The number of resurfacer coats depends on the condition of the base.

The Cushioned Layers

For enhanced player comfort, cushioned systems are a popular choice. These layers are made of acrylic binders mixed with fine rubber granules. Applied between the resurfacer and color coats, they create a surface that absorbs impact, reducing stress on the ankles, knees, and lower back. Reputable tennis court flooring suppliers offer systems with varying levels of cushion to meet different needs.

Expert Tip: The number of cushioned layers directly correlates to the level of shock absorption. More layers create a softer, more forgiving court, ideal for recreational play and senior players. Fewer layers offer a firmer, faster surface suited for competitive training.

The Color Coats

These are the layers that give the court its vibrant, uniform appearance. These coats use highly pigmented, 100% acrylic formulas that also define the court’s playability. The texture of the color coats comes from adding a specific size and amount of silica sand. This texture dictates the speed of play and provides the necessary grip for safe footwork.

- More Sand: Creates a rougher texture, leading to higher friction. This slows down the ball and results in a higher bounce—a “slow” court.

- Less Sand: Creates a smoother texture with less friction. The ball stays lower and travels faster—a “fast” court.

The Line Paint

The final step is the application of the playing lines. This is a specialized, highly pigmented white or yellow acrylic paint that is crisp, durable, and textured to be non-slip. The accuracy of these lines is paramount for fair play.

By manufacturing each of these components with precision, we empower applicators to build a tennis court that is a cohesive, high-performance system from the base up.

Hard Courts vs. Cushioned Courts: Choosing the Right System

When you connect with tennis court flooring suppliers, one of the first discussions will revolve around whether to opt for a standard hard court or a cushioned court. Both are types of synthetic acrylic surfaces, but they offer distinct playing experiences.

| Feature | Standard Hard Court | Cushioned Court |

|---|---|---|

| Composition | Acrylic layers applied directly over the base. | Additional layers of rubber granules mixed with acrylic binders are installed beneath the color coats. |

| Player Comfort | Firm and fast. Offers minimal shock absorption. | Excellent shock absorption, reducing fatigue and stress on joints. |

| Speed of Play | Generally faster, with a lower ball bounce. | Tends to be slightly slower, with a higher ball bounce due to the surface’s energy absorption. |

| Best Suited For | Professional tournaments, competitive training facilities, and players who prefer a fast-paced game. | Clubs, schools, residential courts, and facilities catering to a wide range of player ages and abilities. |

| Maintenance | Standard cleaning and periodic resurfacing. | Same maintenance as a hard court. The cushioned layers are protected by the top coats. |

The choice between a hard court and a cushioned court depends entirely on the intended use of the facility and the priorities of its users. A cushioned court represents a significant upgrade in player comfort and safety, making it an increasingly popular choice for multi-purpose facilities and private clubs. As a manufacturer, we produce the materials for both standard and premium cushioned systems, allowing clients to specify the exact performance they require.

Transform Your Sports Facility Today!

Contact us for high-quality synthetic sports flooring material and elevate your space!

Key Factors to Evaluate When Selecting Tennis Court Flooring Suppliers

The market has numerous companies claiming to be tennis court flooring suppliers. However, discerning clients must look beyond marketing claims and evaluate potential partners based on tangible factors. A thorough evaluation ensures you are sourcing materials that will deliver performance, durability, and value.

Product Range and Specialization

Does the supplier specialize in sports flooring, specifically for tennis? A manufacturer with a dedicated focus on synthetic acrylic systems will have a deeper understanding of the product’s chemistry and performance attributes. Look for a supplier who offers a complete range of products, including:

- Primers and adhesion promoters

- Resurfacers and fillers

- Multiple color options with high-quality pigments

- Line-marking paint

- Materials for both standard hard courts and cushioned systems

This comprehensive offering indicates a thorough understanding of the entire court-building process.

Manufacturing Standards and Quality Control

The quality of a tennis court is only as good as the materials used. Therefore, the supplier’s manufacturing process is of utmost importance. Inquire about their quality control (QC) procedures.

- Raw Material Sourcing: Where do they source their acrylic binders, pigments, and aggregates? Reputable suppliers use only premium-grade raw materials.

- Batch Consistency: What measures are in place to ensure that every batch of material produced has the same color, viscosity, and performance characteristics? Inconsistent batches can lead to a patchy, uneven court.

- Testing: Do they conduct rigorous testing on their products? This should include tests for weatherability, flexibility, hardness, and colorfastness.

As a leading manufacturer, Elitecourt’s production facility adheres to strict QC protocols at every stage, from raw material inspection to final product packaging. This guarantees that every pail of material we supply is of the highest possible standard.

Technical Support and Documentation

While a manufacturer may not install the court, their role doesn’t end once the materials are shipped. Premier tennis court flooring suppliers provide comprehensive support to the applicators and contractors who perform the installation. This includes:

- Detailed Technical Data Sheets (TDS): These documents provide crucial information on product properties, coverage rates, and mixing instructions.

- Application Methodologies: Clear guidelines on how to properly apply each layer of the system for optimal results.

- Access to Technical Experts: The ability to speak with a technical representative to troubleshoot issues or clarify application procedures is invaluable.

This level of support ensures that the high-quality materials are used correctly, leading to a flawless final surface.

Reputation and Industry Standing

A supplier’s reputation is built over years of consistent performance. Look for a manufacturer with a proven track record. While we cannot mention specific projects, a supplier’s longevity and standing in the sports infrastructure community speak volumes. Their dedication to product reliability and customer satisfaction sets them apart. A strong market presence shows that countless clients have tried, tested, and trusted their products over time. This history is a strong indicator of their ability to deliver on their promises.

Adherence to Global Standards

Top-tier tennis court flooring suppliers often formulate their products to meet or exceed the standards set by global sports governing bodies like the International Tennis Federation (ITF). The ITF classifies court surfaces based on their speed of play, ranging from Slow (Category 1) to Fast (Category 5). A supplier who intends their products to meet these classifications shows a commitment to providing surfaces suitable for every level of play, from recreational to professional. When a manufacturer formulates materials to align with ITF Court Pace Rating categories, it shows a deep understanding of the technical requirements of the sport.

The Manufacturing Process: From Raw Materials to a World-Class Surface

Understanding how synthetic acrylic flooring is made provides a deeper appreciation for the quality and technology involved. As one of India’s premier tennis court flooring suppliers, our manufacturing process is a blend of chemical science and precision engineering.

Step-1: Formulation and Raw Material Selection

It all begins in the laboratory. Our chemists formulate specific recipes for each product in the system. The primary ingredient is the 100% acrylic emulsion binder. This is the backbone of the flooring, providing adhesion, flexibility, and weather resistance. We then select other key raw materials:

- Pigments: These are not simple dyes. We use high-quality, inorganic pigments that are incredibly stable and resistant to fading from UV radiation. This ensures the court’s color remains rich and vibrant for years.

- Aggregates: Finely graded silica sand and rubber granules are chosen for their specific size, shape, and hardness. The sand creates the textured surface for grip and pace control, while the rubber provides cushioning.

- Additives: A host of specialty additives are incorporated to enhance specific properties. These can include UV stabilizers, flow and leveling agents, and biocides to prevent the growth of algae and fungus.

Step-2: High-Shear Dispersion

The selected raw materials are loaded into large, high-speed dispersers. These machines use immense mechanical force to mix the components into a stable, homogenous liquid. This process plays a critical role in evenly distributing the pigments and aggregates throughout the acrylic binder. Improper dispersion can lead to color variations, texture inconsistencies, and premature product failure.

Step-3: Quality Control Testing

A sample is taken from every single batch produced. This sample undergoes a battery of tests in our QC lab. We check for:

- Viscosity: To ensure the product has the right consistency for easy application.

- Color Matching: The color is checked against a master standard using a spectrophotometer to guarantee color consistency from batch to batch.

- Dry Time: To ensure it cures at the correct rate.

- Flexibility and Hardness: A film is cast and tested to ensure it has the right mechanical properties once cured.

Only after a batch passes all QC tests is it approved for packaging.

Step-4: Packaging and Shipping

We filter the finished product one last time before we fill it into sealed, durable pails. We label each pail with the product name, batch number, and manufacturing date to ensure complete traceability. Then, we prepare them for shipment to project sites across the country.

This meticulous, quality-driven process is what separates a top-tier manufacturer from a simple reseller. When you source materials from a true manufacturer, you get a product that the team has engineered, produced, and tested to deliver elite performance.

Transform Your Sports Facility Today!

Contact us for high-quality synthetic sports flooring material and elevate your space!

Common Misconceptions About Tennis Court Flooring

When choosing tennis court flooring, several misconceptions can lead facility owners astray. As knowledgeable tennis court flooring suppliers, we feel it’s essential to address and clarify these myths:

Myth 1: “Any good exterior paint will work for a court.”

Reality: Regular exterior paints lack the specialized properties—such as flexibility, abrasion resistance, proper texture, and chemical bonding—required for tennis courts. Using them leads to peeling, cracking, and unsafe surfaces. Always opt for materials specifically engineered by expert tennis court flooring suppliers.

Myth 2: “Thicker courts are always better.”

Reality: Thickness alone doesn’t guarantee performance or longevity. The real benefits come from the quality and composition of each layer. Well-engineered systems, even with fewer layers, surpass thicker but inferior materials.

Myth 3: “Darker courts get too hot to play.”

Reality: Modern acrylic systems use advanced pigments that reduce heat absorption, even in dark colors. Solar-reflective pigments make a range of colors practical for different climates.

Myth 4: “Cushioned courts require much more maintenance.”

Reality: Cushion layers are protected within the flooring system. Maintenance is nearly identical to hard courts—cleaning and periodic resurfacing—ensuring long-lasting performance.

Understanding these facts allows facilities to avoid costly mistakes and ensures the selection of reliable, high-performance court materials from trusted tennis court flooring suppliers.

The Importance of Maintenance for Longevity

Sourcing premium materials from a trusted supplier is the first step. The second is implementing a proper maintenance program to protect that investment. Even the highest quality synthetic acrylic surface requires regular care to maintain its playability, appearance, and longevity. Neglecting maintenance can lead to premature wear, reduced player safety, and the need for more frequent and expensive resurfacing.

Here are the key maintenance practices for a synthetic acrylic tennis court:

Regular Cleaning (Weekly/Bi-Weekly)

The most important maintenance task is keeping the court clean. Debris like leaves, twigs, and dirt can be abrasive under players’ feet, acting like sandpaper to wear down the surface. They can also trap moisture, promoting the growth of algae or mold.

- Use a leaf blower to remove loose debris.

- For more stubborn dirt, a soft-bristled broom or a water broom can be effective.

- Rinse the court periodically with clean water.

Stain and Contaminant Removal

Address spills and stains immediately. Things like soft drinks, bird droppings, or suntan lotion can stain the surface or make it slippery.

- Use a mild solution of household detergent and water.

- Gently scrub the affected area with a soft brush.

- Rinse thoroughly with clean water to remove all soap residue, as soap can leave a slippery film.

Managing Vegetation and Water

- Ensure that the area around the court is free from overhanging trees and encroaching grass, which contribute to debris.

- Check that the court’s drainage system is working correctly. Standing water is the enemy of a tennis court surface. Puddles can lead to staining, delamination over time, and create a breeding ground for mildew.

Expert Tip: Never use a high-pressure washer to clean your court. The intense pressure can damage the textured surface, blasting away the fine silica sand and potentially forcing water into the substrate. A standard garden hose with a spray nozzle or a low-pressure water broom is sufficient.

Periodic Professional Resurfacing

Over years of play and exposure to the elements, the top color coats will gradually wear down. The color may fade, and the texture may become smooth, affecting ball speed and player grip. This is normal. Most synthetic acrylic courts require resurfacing every 5–8 years, depending on usage and climate.

Resurfacing involves:

- Thoroughly cleaning the court.

- Making any minor repairs to cracks or depressions.

- Applying new resurfacer and color coats to restore the court’s texture, color, and playability.

By following a simple but consistent maintenance schedule, you can significantly extend the life of your court and ensure it continues to provide a top-quality playing experience for years to come. As your materials manufacturer, we design our products for durability, but proper care is the key to unlocking their full lifespan.

Transform Your Sports Facility Today!

Contact us for high-quality synthetic sports flooring material and elevate your space!

FAQs

Asphalt or concrete, constructed with proper drainage and slope, provide a stable foundation for acrylic court surfaces.

A quality acrylic surface typically lasts 5 to 8 years before requiring resurfacing, depending on usage and maintenance.

Yes, the court speed can be changed by altering the sand content in the topcoat during resurfacing.

Modern surfaces are water-based, low-VOC, and free of harmful substances, making them safe and eco-friendly.

Specialists ensure consistent quality, product expertise, and surfaces engineered specifically for tennis courts.