How to Start a Running Track?

Table of Contents

Creating a running track from scratch is an exciting yet complex endeavor. Whether you’re an architect, facility manager, or athletic director, the process of designing and building a high-quality running track requires precision, knowledge, and attention to detail. A modern running track isn’t just about marking lanes on the ground; it’s about selecting the right materials, designing a safe and efficient layout, and ensuring long-term durability. One of the best materials for building a top-tier running track is synthetic acrylic flooring, known for its resilience, safety features, and ease of maintenance.

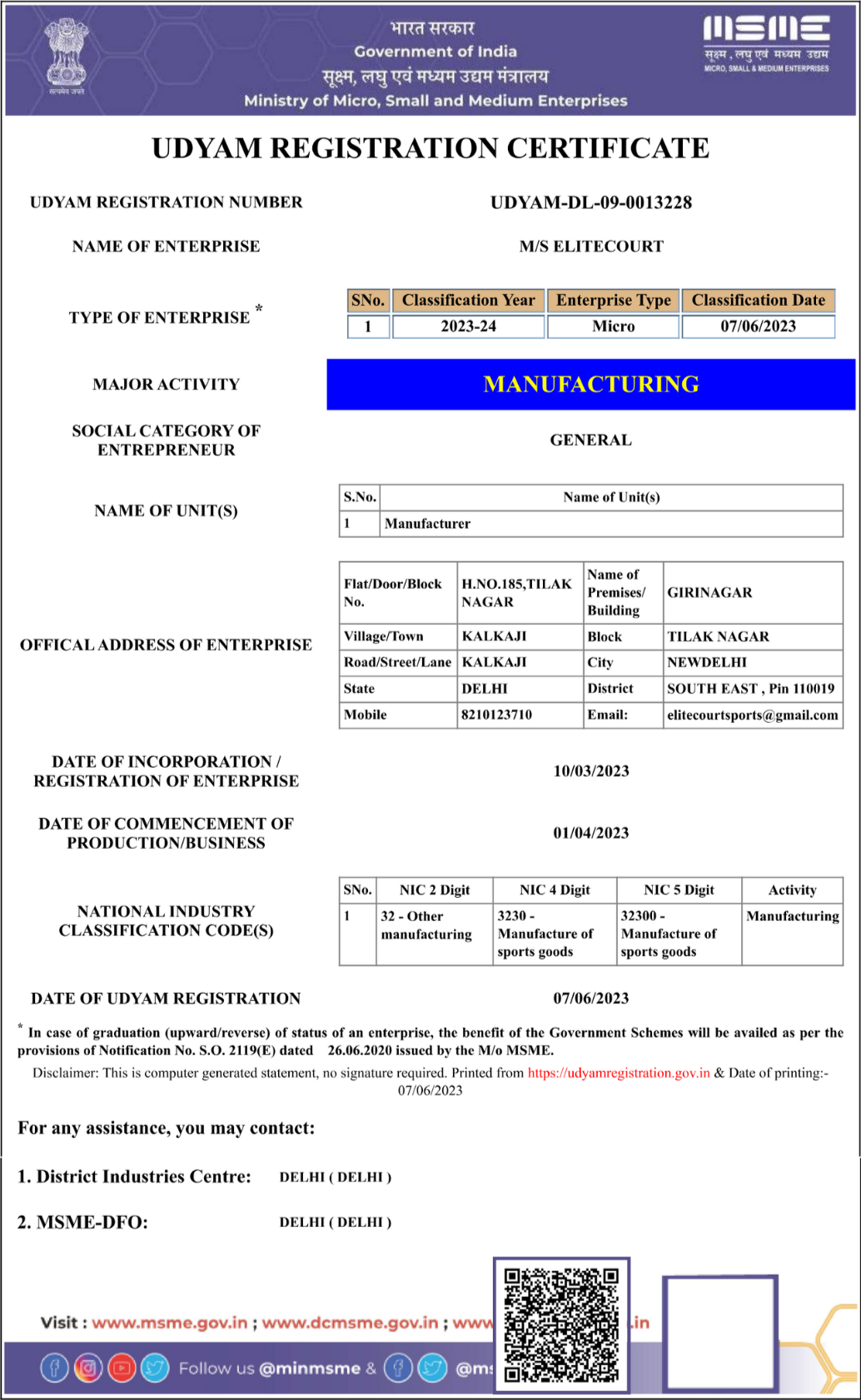

At Elitecourt, we specialize in manufacturing synthetic acrylic sports court flooring materials designed to meet the needs of athletes, recreational users, and sports institutions. Our innovative solutions for track surfaces help facilities achieve a perfect balance between performance and aesthetics. In this comprehensive guide, we will discuss the essential steps for starting a running track, from design considerations to choosing the right synthetic acrylic material. Let’s dive in!

Why Choose Synthetic Acrylic Sports Flooring for Your Running Track?

When you decide to build or renovate a running track, selecting the right surface material is paramount. The surface not only influences performance but also determines the track’s longevity and safety. Synthetic acrylic flooring is an excellent option for several reasons:

Durability and Longevity

Designers create synthetic acrylic flooring to withstand heavy foot traffic and exposure to the elements. Unlike other materials, which degrade or become slippery over time, acrylic floors last longer. Whether the track faces extreme temperatures, heavy rainfall, or intense sunlight, synthetic acrylic surfaces maintain their structural integrity for years.

Superior Safety Features

Safety is the number one priority for any athletic facility. Synthetic acrylic running tracks provide excellent shock absorption, reducing the risk of injuries like sprains and joint pain. This surface minimizes the impact on an athlete’s body, especially during long-distance runs or intense sprints.

Moreover, acrylic flooring offers excellent traction, which prevents runners from slipping or sliding, a critical safety feature that enhances overall performance.

Customization Options

Synthetic acrylic flooring offers high versatility, and you can customize the surface to meet specific needs. Whether you build a professional-grade 400-meter oval track or a smaller recreational track, you can tailor the acrylic flooring to suit your space. Additionally, you can customize colors and markings to fit specific aesthetics or comply with official regulations for sports events.

Cost-Effectiveness

While synthetic acrylic flooring might have a higher initial cost compared to some other track materials, the benefits far outweigh the investment. Synthetic tracks require little maintenance, are resistant to weathering, and have a much longer lifespan. Over time, this reduces the overall cost of ownership, making it a wise financial decision for athletic facilities.

Low Maintenance Requirements

Maintaining a synthetic acrylic track is easier compared to other materials like asphalt or rubber. You can clean the track’s smooth surface using simple tools like brooms, leaf blowers, or water hoses. For more stubborn dirt, a mild detergent solution can restore the surface to its original condition.

Transform Your Sports Facility Today!

Contact us for high-quality synthetic sports flooring material and elevate your space!

Key Factors to Consider When Starting a Running Track

Starting a running track requires careful planning and an understanding of the key elements involved. Here are some essential factors to keep in mind:

Track Design and Layout

The layout of your running track will depend on the available space and intended use. A standard competitive running track is an oval shape with a total length of 400 meters, measured along the innermost lane. However, there are variations in track design that may be needed for different sports complexes or educational institutions.

Key elements to consider when planning the track layout:

- Lane Number and Width: Most competitive tracks feature 8-9 lanes, each 1.22 meters wide. However, recreational tracks may only feature 4-6 lanes depending on the available space and budget.

- Curvature: Tracks include both straight and curved sections. The radius of the curves should be uniform to allow runners to maintain their speed and minimize strain on their bodies. The radius should ideally be between 30-50 meters for optimal performance.

- Banking: The bank (or slope) on curves helps athletes maintain their speed by providing centrifugal force. A slight banking is necessary to create a smooth transition between straight and curved sections.

- Markings and Lane Division: Ensure that all lane markings are precise and meet official competition regulations. These markings must be clearly visible and of high contrast for easy visibility during competitions.

Choosing the Right Sub-Base

The sub-base is a critical component in the construction of a running track. It provides a stable foundation for the track’s surface and ensures proper water drainage. The sub-base typically consists of compacted layers of gravel, sand, and crushed stone. Proper compaction is necessary to prevent the sub-base from shifting under pressure, which could lead to the surface cracking or sinking over time.

A well-constructed sub-base also promotes proper drainage, preventing the accumulation of water, which can degrade the track surface. Depending on the local climate and soil conditions, additional measures may be necessary to prevent moisture buildup, such as drainage pipes or a perforated drainage system.

The Process of Building a Running Track

Now that you understand the factors involved in creating a running track, let’s dive deeper into the process itself. Below are the essential steps to building a running track:

Site Selection and Ground Preparation

The first step in creating a running track is choosing a suitable site. A flat, level area is ideal, though if you are working with a hilly or uneven landscape, additional work may be required to level the ground.

After choosing the site, you must clear the ground of debris, rocks, and vegetation. Remove any existing grass or trees to make way for the track’s sub-base. Site preparation may involve earth-moving equipment to grade and shape the land to accommodate the track.

Track Layout and Surveying

Accurate measurement is essential to ensure that the running track is built to the correct specifications. Surveying equipment, including lasers and GPS technology, helps mark the track’s exact location, lane measurements, and curvature. For competitive tracks, it’s important to ensure that the curve radii are correct for consistent performance.

The layout should be clearly marked on the ground before the sub-base is installed, allowing for the proper placement of the track and its components.

Installing the Sub-Base

After marking the layout, you install the sub-base. Typically, workers install it in layers, starting with coarse crushed stone and followed by finer gravel or sand. You must compact the layers to provide a stable foundation for the track’s surface. This process often involves the use of heavy machinery to ensure uniform compaction.

Applying the Synthetic Acrylic Surface

The next step is to apply the synthetic acrylic track surface. This process begins with a primer coat, followed by layers of specialized acrylic material. Designers create each layer to provide traction, cushioning, and durability. Professionals apply the acrylic surface in multiple stages to ensure a uniform, smooth finish. Only experienced professionals should apply the surface to ensure no air pockets or imperfections remain.

Painting Track Markings

After the acrylic surface installs and cures, workers paint lane markings, starting lines, and other necessary symbols on the track. These markings should follow competition regulations if the track will be used for official races.

The color contrast of lane markings and the start/finish lines is critical for visibility. Bright colors like white, yellow, or red are often used to ensure clarity.

Final Inspections and Quality Assurance

Before the track is open for use, a final inspection is conducted to ensure that all specifications are met. This includes checking the surface for smoothness, verifying the lane widths and markings, and ensuring that the track is level and properly banked. Any necessary adjustments are made at this stage.

Transform Your Sports Facility Today!

Contact us for high-quality synthetic sports flooring material and elevate your space!

Benefits of Investing in a Synthetic Acrylic Running Track

A synthetic acrylic running track offers several compelling advantages over traditional surfaces:

Performance and Comfort

Acrylic surfaces provide a cushioned running experience, absorbing the impact from each stride. This reduces the risk of long-term joint injuries and enhances athletic performance.

Weather Resistance

One of the main benefits of synthetic acrylic flooring is its ability to withstand extreme weather conditions. Whether it’s blazing sunshine or heavy rainfall, the acrylic surface remains unaffected, ensuring consistent performance year-round.

Aesthetic Appeal

Synthetic acrylic running tracks come in a variety of color options. From bright red to classic blue, you can design your track to fit the visual theme of your sports facility.

Low Maintenance

Compared to other track surfaces, synthetic acrylic tracks are easier and less expensive to maintain. Routine cleaning, minor repairs, and periodic resurfacing are all that’s needed to keep the track in top condition.

Maintenance and Care for Synthetic Acrylic Running Tracks

To keep your synthetic acrylic track in pristine condition, regular maintenance is essential. Here’s how to care for your track:

Regular Cleaning

Dirt and debris can accumulate on the track, especially after storms or heavy foot traffic. A basic cleaning routine involves sweeping the track with a soft broom, or using a leaf blower to remove leaves and dust. A power washer can also be used to clean stubborn dirt from the surface.

Resurfacing

Over time, synthetic acrylic surfaces may experience minor wear. Resurfacing the track restores its original finish and helps ensure a safe and smooth surface for athletes.

Seasonal Inspections

Before each season, perform a thorough inspection of the track to look for any signs of damage or wear. Check for cracks, faded markings, or drainage issues that could affect performance.

FAQs

Contractors commonly construct running tracks using materials like synthetic rubber, polyurethane, and acrylic. Many favor synthetic acrylic surfaces because of their durability, safety features, and ease of maintenance.

A well-maintained synthetic acrylic track can last between 10 to 15 years, depending on the level of use, weather conditions, and maintenance practices.

Installing a running track is a complex process that involves ground preparation, sub-base installation, and laying synthetic surfaces. It is recommended to hire a professional company with experience in building athletic tracks.

Yes, synthetic acrylic surfaces are eco-friendly because they are made from recyclable materials and can be maintained with minimal impact on the environment.

Conclusion

Building a running track involves thoughtful planning, expert execution, and careful selection of materials. Synthetic acrylic flooring is an ideal choice for creating a high-performance, long-lasting, and aesthetically pleasing running track. Whether you’re designing a track for competitive athletes or recreational use, a synthetic acrylic track provides the perfect surface to meet all your needs. Elitecourt offers top-quality synthetic acrylic flooring that ensures safety, durability, and outstanding performance for any running track project.

Relevant Link: World Athletics – Track & Field Guidelines