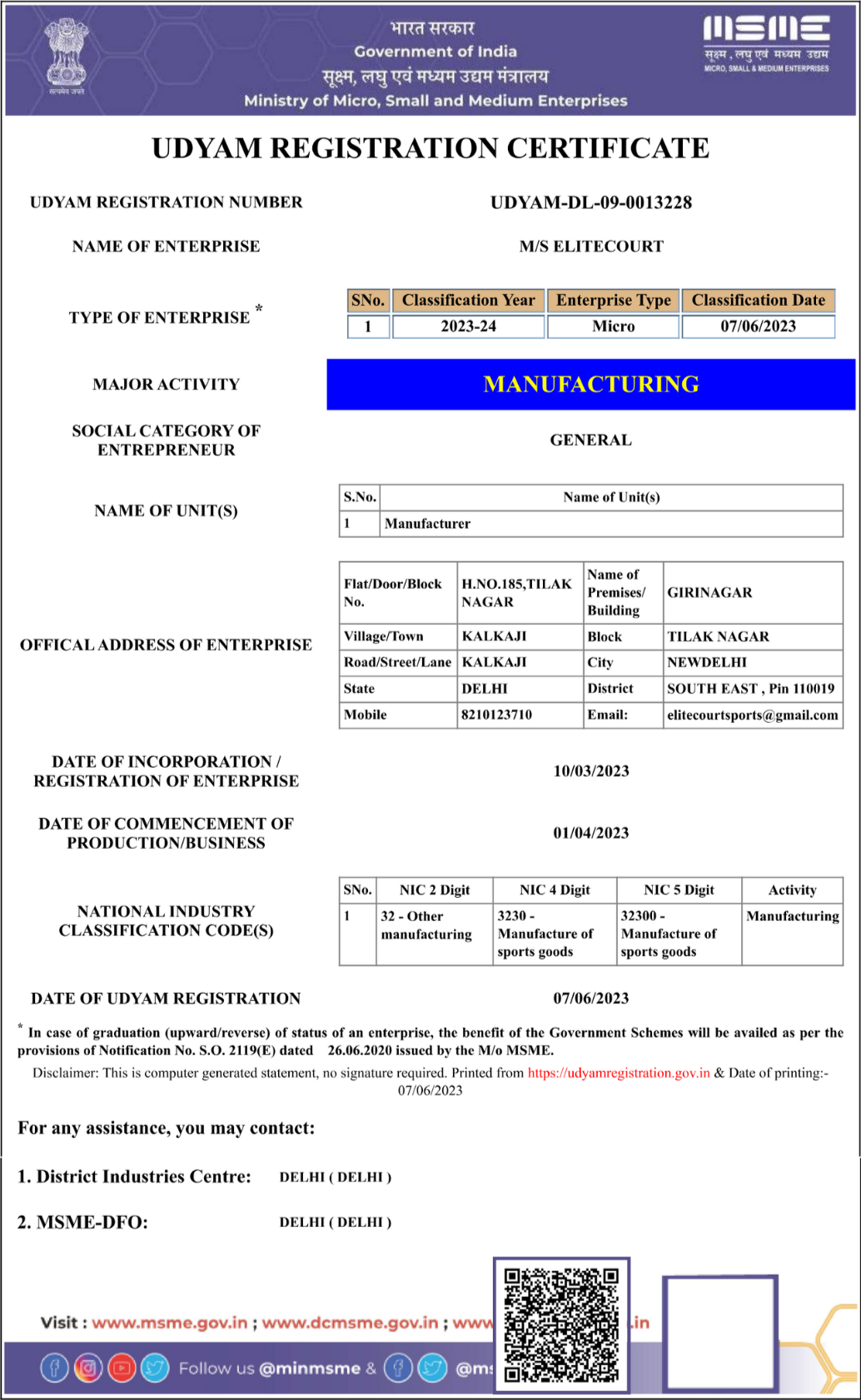

Court Pickleball Flooring Material Manufacturers in India

Elitecourt specializes in premium synthetic acrylic sports flooring for pickleball, tennis, basketball, and multi-sport courts across India. Years of experience with high-performance acrylic systems and technical specifications establish proven reliability for court pickleball projects.

Table of Contents

Elitecourt manufactures synthetic acrylic court pickleball flooring materials in India, engineered for consistent ball bounce, reliable grip, and long‑lasting outdoor performance. With dedicated systems for pickleball and multi‑sport courts, Elitecourt supports clubs, schools, and residential communities that want professional‑grade playing quality without handling installation in‑house.

What is a court pickleball surface?

A court pickleball surface is the finished playing area on which pickleball is played, typically built over a concrete or asphalt base and coated with specialized acrylic sports flooring material. For modern facilities, acrylic sports coatings are preferred because they offer a uniform texture, predictable ball bounce, UV resistance, and slip‑resistant grip tailored to pickleball’s pace and lateral movement.

Most outdoor court pickleball projects in India follow this basic structure:

- Engineered base (concrete or asphalt) with proper slope and drainage

- Acrylic resurfacer coats to correct micro‑imperfections and create texture

- Color topcoats that define the playing area with contrasting tones

- Line markings laid to official pickleball dimensions and standards

Within this framework, Elitecourt supplies the specialized acrylic materials used from the primer to the color coats, ensuring a continuous, compatible system from bottom to top for court pickleball projects.

Why court pickleball needs specialized acrylic flooring

Court pickleball looks deceptively simple, but the sport places unique demands on the surface that general‑purpose paint or generic outdoor coatings cannot handle. A well‑engineered acrylic system is essential for three critical reasons: performance, player safety, and durability under Indian climate conditions.

Key performance and safety expectations for court pickleball:

- Consistent ball bounce across the entire court, with minimal dead spots or hot spots.

- Optimized surface friction that provides grip for quick stops and lateral cuts, without being so abrasive that it causes excessive skin burns during falls.

- Predictable traction in dry and slightly damp conditions, helping reduce slips when players accelerate or change direction sharply.

From a durability perspective, India’s mix of high heat, monsoon moisture, and UV intensity can quickly degrade inferior coatings. Therefore, court pickleball flooring materials must be:

- UV‑stable to resist fading and chalking

- Flexible enough to cope with thermal movement

- Resistant to surface micro‑cracking and peeling when applied correctly

Elitecourt designs its acrylic sports flooring systems to address these needs by combining high‑quality acrylic binders, pigments, and graded silica to deliver long‑term performance on court pickleball surfaces.

Expert tip: When planning a court pickleball project, prioritize a complete, compatible acrylic system from a single manufacturer instead of mixing unrelated primers, resurfacers, and color coats from different brands. This reduces adhesion problems and simplifies technical support over the court’s life.

Elitecourt’s role in court pickleball projects

Elitecourt’s core role is manufacturing and supplying synthetic acrylic sports court flooring materials suitable for outdoor sports including pickleball. The brand does not perform on‑site construction or installation; instead, it equips contractors, sports consultants, and facility owners with high‑performance materials and technical data for court pickleball surfaces.

How Elitecourt fits into a typical court pickleball project:

- A club, school, or community finalizes layout and base construction with a civil contractor.

- The project team selects Elitecourt acrylic products as the finishing system for the court pickleball surface.

- Approved applicators or flooring contractors apply Elitecourt’s primers, resurfacers, cushion coats (if specified), and color topcoats as per datasheets.

Because Elitecourt focuses solely on material quality and technical specifications, facility owners gain access to a manufacturer that continuously refines acrylic formulations for performance sports use, rather than a generic paint supplier.

Transform Your Sports Facility Today!

Contact us for high-quality synthetic sports flooring material and elevate your space!

Core characteristics of a high‑quality court pickleball surface

A well‑designed court pickleball surface combines playability, comfort, and long‑term structural integrity. Elitecourt’s acrylic systems are engineered to help installers achieve these characteristics consistently.

Ball bounce and speed

Pickleball demands a firm yet responsive surface that provides a reliable bounce with limited energy absorption.

- Too soft a surface (for example, excessively cushioned) can slow the ball and change the feel of rallies.

- Too hard and glossy a surface can cause erratic bounce and slippery play, especially with dust or light moisture.

Elitecourt’s acrylic color coats are designed to maintain a balanced firmness and micro‑texture, aligning with performance norms referenced by ASTM guidelines and All India Pickleball Association expectations.

Surface texture and grip

Texture is controlled through the particle size and distribution of silica within resurfacer and topcoat layers.

- A good court pickleball system uses texture to create grip without aggressive roughness that accelerates shoe wear and skin abrasions.

- Properly textured Elitecourt layers help players accelerate, decelerate, and pivot while minimizing slip risks.

Color visibility and contrast

Court pickleball lines and zones must be clearly visible under sun, shade, and artificial lighting.

- Acrylic systems like Elitecourt’s are pigmented in high‑visibility, UV‑stable colors for courts and run‑off zones.

- Contrasting line colors help players judge boundaries quickly, improving reaction time and reducing decision errors during fast rallies.

Weather and UV resilience

Outdoor court pickleball facilities in India face:

- High summer temperatures

- Intense UV exposure

- Monsoon rain and surface dampness

- Dust and pollution accumulation

Elitecourt’s acrylic formulations are designed for excellent UV resistance, color retention, and resistance to chalking and blistering when properly applied over sound bases. Regular cleaning and periodic recoating extend performance over many seasons.

Anatomy of an acrylic court pickleball system

While installers adapt layer counts to budget and performance goals, the structure of an acrylic pickleball system generally follows a sequence similar to Elitecourt’s multi‑layer sports flooring designs.

Typical layer build‑up

- Acrylic primer / adhesion promoter

- Applied over concrete or asphalt to enhance bonding and seal minor surface porosity.

- Essential for long‑term adhesion and to reduce blistering or peeling.

- Acrylic resurfacer layers (with silica)

- One or more coats smooth the base, fill hairline voids, and introduce the desired texture profile.

- A critical step for achieving the uniform, non‑glare finish expected in modern court pickleball venues.

- Optional cushion coats

- Multiple intermediate layers formulated with elastomeric components or rubber granules.

- Increase shock absorption and comfort, particularly valued for training courts and facilities serving older or recreational players.

- Acrylic color topcoats

- 100% acrylic color layers with pigments and fine texture, forming the visible playing surface.

- Provide UV resistance, skid resistance, and the final visual identity of the court pickleball surface.

- Line marking coats

- High‑contrast, acrylic line paints applied to official pickleball dimensions.

- Precision in layout is critical for compliance and player confidence.

Elitecourt’s technical sheets provide guidance on layer sequence, coverage rates, recommended mixing ratios, and curing intervals, helping installers deliver uniform results on court pickleball projects.

Court pickleball dimensions, layout, and standards

Standardization forms the foundation of competitive pickleball, ensuring fair play through precise court layouts aligned with official guidelines from organizations like USA Pickleball. While Elitecourt supplies premium synthetic acrylic materials rather than layout or construction services, understanding these exact dimensions helps planners select compatible flooring systems for optimal performance.

Official court pickleball playing area dimensions

The standard pickleball court measures 20 feet (6.10 m) wide by 44 feet (13.41 m) long for both singles and doubles matches, with all lines exactly 2 inches (5.08 cm) wide in a color contrasting the surface. Court measurements are taken to the outside edges of perimeter and non-volley zone lines, creating a total playing surface area of approximately 880 ft² (81.8 m²).

Key zones and markings

- Non-volley zone (kitchen): Extends 7 feet (2.13 m) from the net on both sides, measuring 20 feet wide by 7 feet deep; players cannot volley the ball while standing in this zone.

- Service boxes: Each side features two boxes, 10 feet (3.05 m) wide by 15 feet (4.57 m) long (from kitchen line to baseline), split by a centerline.

- Baselines and sidelines: Define the full 20 ft x 44 ft rectangle, with the centerline running the full length for service court division.

Net specifications

The net spans up to 22.5 feet (6.86 m) wide (at least 20 feet 9 inches), tensioned taut with heights of 36 inches (91.44 cm) at the sidelines/posts and 34 inches (86.36 cm) at the center. Posts are positioned outside the court boundaries, centered along the width.

Recommended surrounding space

For safe play, allocate a minimum total area of 30 feet wide by 60 feet long per court, with preferred dimensions of 34 feet wide by 64 feet long including run-off zones (at least 10 feet on sides and 20 feet behind baselines). This buffer prevents injuries during dives and sprints, especially in multi-court facilities.

For authoritative diagrams and tolerances, refer to USA Pickleball official resources, which serve as the global benchmark and are often adopted for Indian projects seeking competition readiness (USA Pickleball court specifications). Elitecourt’s acrylic court pickleball materials are engineered to deliver uniform texture, grip, and bounce across these precise dimensions, supporting everything from recreational community courts to tournament venues.

Surface options for court pickleball: why acrylic stands out

Several surface types can be used for court pickleball, but acrylic sports coatings over concrete/asphalt bases have emerged as the preferred choice for clubs, schools, and communities seeking a balance of performance, maintenance, and aesthetics.

Common pickleball surface categories

| Surface type | Key traits for court pickleball | Pros | Limitations |

|---|---|---|---|

| Acrylic coatings | Firm, textured, UV‑stable over concrete/asphalt | Tournament‑style bounce; rich color options; simple maintenance; proven durability | Requires proper base preparation |

| Concrete/Asphalt base | Stable foundation for acrylic systems | Industry standard; excellent load support; proper drainage when sloped correctly | Must be coated for playability |

| Modular tiles | Interlocking plastic over base | Fast installation | Different ball feel; traps dirt; higher maintenance |

| Indoor wood/vinyl | Used in multi‑use halls | Good for indoor multi‑sport | Not suitable for outdoor court pickleball |

Acrylic sports flooring over concrete/asphalt bases, such as Elitecourt’s systems, is widely favored for dedicated court pickleball projects because it delivers:

- Predictable ball bounce close to tournament expectations.

- Customizable texture and cushioning, allowing different configurations for training or competition.

- Vibrant, long‑lasting colors that enhance branding and visibility.

Transform Your Sports Facility Today!

Contact us for high-quality synthetic sports flooring material and elevate your space!

Where court pickleball flooring is used in India

Pickleball’s rapid growth in India has led to demand for dedicated court pickleball surfaces across multiple facility types. As a manufacturer of acrylic sports flooring materials, Elitecourt serves a wide variety of spaces that require durable, high‑quality coatings.

Common venues using acrylic court pickleball systems:

- Schools and universities: Adding pickleball to existing sports infrastructure to diversify physical education and co‑curricular programs.

- Residential societies and townships: Creating inclusive community courts suitable for players of all ages and abilities.

- Sports clubs and academies: Developing training environments with multiple courts, often combining tennis, basketball, and court pickleball facilities.

- Corporate and institutional campuses: Building recreational amenities that promote employee wellness and engagement.

Elitecourt’s synthetic acrylic materials are designed to function reliably across these varied environments, making them a strong option for planners seeking versatile, multi‑sport‑ready court pickleball flooring solutions.

Planning a court pickleball project: key decisions

Even though Elitecourt does not carry out installation, the brand’s materials are frequently specified by consultants and project owners during the early planning phase. When designing a court pickleball facility, planners must consider several interdependent factors.

New construction vs. conversion

- New build courts involve creating a dedicated pickleball layout from scratch with optimized orientation, drainage, and sub‑base.

- Conversions might adapt tennis, basketball, or multi‑purpose courts by re‑marking surfaces and adjusting net systems.

In both cases, Elitecourt acrylic materials can be used as the finishing system over compatible bases, subject to proper surface preparation.

Outdoor vs. indoor court pickleball

- Outdoor courts typically use concrete or asphalt with acrylic coatings designed to withstand UV and weather.

- Indoor courts may rely on wood, vinyl, or synthetic surfaces; acrylic is less common indoors but can be used in some covered settings with appropriate base preparation.

Elitecourt’s core expertise lies in outdoor acrylic sports flooring, which aligns naturally with India’s rising demand for open‑air court pickleball facilities.

Single vs. multi‑sport usage

Many complexes want a multi‑use surface that supports pickleball plus sports like tennis or basketball.

- Elitecourt acrylic systems can be tuned in texture and cushioning to accommodate different use mixes.

- Line layouts can layer pickleball markings atop existing tennis or multi‑sport courts, provided visibility and player comprehension are not compromised.

Court pickleball surface preparation – why it matters

Surface preparation is one of the most critical stages of any court pickleball project, often determining how long the final system will last before major resurfacing is needed. Although installers handle this step, material choices from Elitecourt are optimized for correctly prepared bases.

For a typical outdoor court pickleball surface:

- The base must be structurally sound, free from major cracks, potholes, or moisture problems.

- Dust, oils, and loose particles must be removed through pressure washing and mechanical cleaning.

- Substantial cracks are treated with suitable acrylic patch or crack repair products, and birdbaths are corrected to minimize water ponding.

Only after this groundwork should Elitecourt acrylic primers, resurfacers, and color coats be applied, following recommended film thicknesses and curing windows.

Expert tip: For new concrete bases, allow sufficient curing time and confirm moisture levels before applying acrylic systems on your court pickleball project. Excess trapped moisture can lead to blistering or adhesion failure over time.

Weather and timing for court pickleball coatings

Acrylic coatings are sensitive to environmental conditions during application and curing, particularly in colder or very humid climates. For Indian court pickleball projects, installation partners typically schedule work in windows with stable temperatures and minimal rain risk.

Core timing considerations:

- Temperature: Acrylic systems perform best when applied at moderate temperatures and when the surface is not excessively hot or cold.

- Humidity: Very high humidity can slow down drying and curing, impacting early‑stage film properties.

- Rain and dew: Fresh coatings are vulnerable to wash‑off or surface defects if exposed to rain or heavy dew before initial cure.

Elitecourt provides material guidance that installers can adapt to local conditions, helping ensure that court pickleball surfaces cure properly and reach the designed performance level.

Safety, comfort, and player experience on court pickleball surfaces

A successful court pickleball surface is not measured only by appearance. It must also support safe, enjoyable play across different age groups and skill levels.

Traction and slip resistance

Elitecourt’s textured acrylic layers aim to maintain a balanced coefficient of friction, reducing the risk of slips while avoiding excessive stickiness. Correct footwear and regular court cleaning are still vital to safety, but starting with a purpose‑designed surface dramatically improves baseline traction.

Shock absorption and joint comfort

Cushioned acrylic systems can reduce peak impact forces on knees, ankles, and hips during court pickleball play.

- Facilities serving junior and senior populations, or with intense training schedules, often favor cushioned configurations.

- Elitecourt’s cushioning layers are designed to maintain playability and bounce while adding comfort, rather than creating a soft, unstable feel.

Visual comfort and glare control

Pigment selection and surface texture also influence glare.

- Matte or low‑sheen acrylic finishes reduce eye strain in bright sun.

- Carefully chosen court and perimeter colors help players track the ball against backgrounds more easily.

Transform Your Sports Facility Today!

Contact us for high-quality synthetic sports flooring material and elevate your space!

Maintenance best practices for court pickleball flooring

Even the best acrylic court pickleball surface requires regular maintenance to preserve play quality and appearance. While maintenance tasks are handled locally, Elitecourt’s materials are engineered to respond well to standard cleaning and care routines.

Routine cleaning

- Dry sweeping or blowing to remove dust, leaves, and light debris is recommended several times per week in busy facilities.

- Periodic washing with water and mild detergents helps remove embedded dirt and pollutants that can reduce friction.

- Avoid harsh acids or untested chemicals that might degrade acrylic films.

Inspection and minor repairs

- Inspect for early signs of wear, such as localized color fading, minor surface raveling, or small cracks at stress points.

- Address issues promptly using compatible acrylic patching compounds and spot repairs to prevent further deterioration.

Recoating cycles

Over time, heavy play and environmental exposure will gradually wear down the topmost texture and color layer.

- When traction or appearance noticeably declines, a recoating cycle with fresh acrylic color and texture can restore performance.

- Elitecourt’s acrylic systems are designed so that future recoats can bond well if surface preparation is done correctly.

Expert tip: Keep a simple maintenance log for your court pickleball facility, noting cleaning schedules and any repairs. This helps time recoating cycles accurately and demonstrates care to members and players.

Sustainability and environmental considerations

Court pickleball surfaces increasingly factor in environmental responsibility, from material selection to lifecycle outcomes. Elitecourt’s synthetic acrylic systems are designed to offer durable performance, which reduces the frequency of complete surface replacement.

Sustainability‑related advantages of acrylic court pickleball flooring:

- Long service life when maintained properly, which reduces waste and material usage over time.

- Compatibility with existing concrete or asphalt bases, minimizing the need for full structural reconstruction in many renovation projects.

- Water‑based acrylic formulations (as opposed to solvent‑heavy alternatives) can support lower volatile emissions during application when used correctly by professionals.

By selecting high‑quality materials and ensuring proper installation and maintenance, facility owners extend the usable life of their court pickleball surfaces and reduce long‑term environmental impact.

How Elitecourt supports planners and installers

Although Elitecourt does not install courts, the company plays a proactive role in supporting stakeholders throughout pickleball projects.

Typical ways Elitecourt supports projects:

- Product selection guidance: Recommending suitable systems (for example, training vs. high‑performance configurations) based on intended use and base conditions.

- Technical documentation: Providing specification sheets that detail coverage, mixing, application methods, and curing windows for each product in the system.

- Performance and compliance insights: Sharing information about alignment with standards such as ASTM and AIPA norms relevant to court pickleball play.

This technical backing helps installers and project consultants design robust, standards‑aligned pickleball court solutions while giving owners confidence in the material backbone of their facility.

Multi‑court complexes and court pickleball layouts

Many facilities in India are building multi‑court complexes that combine tennis, basketball, and pickleball on a shared surface. Elitecourt’s acrylic materials lend themselves well to such multi‑use planning due to their flexibility and color options.

Layout considerations for multi‑court sites:

- Design run‑off zones and circulation paths so players can move between courts without crossing active play areas.

- Use distinct color coding for court pickleball layouts versus other sports to reduce confusion.

- Consider orienting courts to minimize glare from morning or evening sun on primary playing directions.

Because Elitecourt specializes in synthetic acrylic sports flooring, the same system can often serve multiple sports with minor adjustments in texture or cushioning, simplifying maintenance and visual harmony across the complex.

Why choose Elitecourt materials for court pickleball

When evaluating materials for a pickleball project, decision‑makers typically compare brands on performance, reliability, and technical backing. Elitecourt offers several clear advantages as a dedicated acrylic sports flooring manufacturer.

Key reasons Elitecourt stands out:

- Specialization in sports acrylics: Elitecourt focuses on synthetic acrylic sports court materials, not general building paints, ensuring formulations tuned for ball sports performance.

- Layered system design: From primers to color coats, products are engineered to work together as a coherent system, reducing compatibility issues on court pickleball projects.

- Standards‑oriented performance: Materials are developed with reference to recognized norms such as ASTM and All India Pickleball Association guidelines for tournament‑grade courts.

- Versatility across sports: The same core acrylic technology successfully supports pickleball, tennis, basketball, volleyball, skating, and jogging tracks, making it ideal for multi‑sport facilities.

These attributes make Elitecourt a reliable choice for owners and consultants who want professional‑grade, durable pickleball flooring backed by a manufacturer with deep sports‑specific experience.

Transform Your Sports Facility Today!

Contact us for high-quality synthetic sports flooring material and elevate your space!

FAQs

Acrylic sports flooring systems over concrete or asphalt bases are ideal for outdoor court pickleball, offering consistent bounce and traction.

No, Elitecourt manufactures materials only. Installation handled by specialized contractors nationwide.

Yes, Elitecourt acrylics work for resurfacing tennis/basketball courts. Proper preparation enables pickleball markings and performance.

High‑quality systems withstand UV, heat, and monsoons. Regular maintenance ensures years of consistent playability.

Yes, they add comfort for training/community courts. Maintain bounce while reducing joint impact during extended play.